Last 1st and 2nd of December, we were honored to receive our distributor in Poland, KTI Implants. He spent a 2-day-training in our facilities to know, at first hand, how we work in DAS.

He was accompanied by professionals of the dental sector who wanted to know all our new products. The workshop was very interesting and enriching due to the interaction between the technicians and our R+D+I engineers. Our engineers asked their questions and found solutions to their everyday work.

The target of the formation was showing all the process from the intraoral scanning of a 3D printed model to the finished milled piece on a validated system.

We started the training with a short presentation of the new products and services that DAS offers: the new 3TiBase® for those cases thar need more cement height, the new intraoral system and the customized CAD-CAM adjustment services.

The attendees could verify that the scanning process of Das intraoral scanbody is very simple and practical. DAS scanbodies offer a connection with the implant unique on the market and allow professionals to capture the position of the implant with maximum guaranteed precision.

We used Carestream Dental scanner for the scanning process.

This video shows the intraoral scanning process in a 3D printed model with our digital analog.

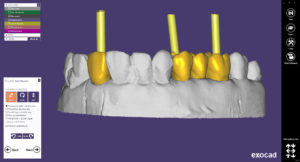

Once finished the scanning process of the scanbodies, we started to design the prothesis using Exocad.

The attendees had the chance to see the design process of an angulated screw channel. They loved the different possibilities that our libreries offer and the fact that there are different CAD softwares available to work with our products.

When the design of the prosthesis was finished, we started to mill the prosthetic part with WorkNC Dental.

The Crown was milled using a Roland DWX-51D. The attendees could see the milling process and the operation of our milling tool: The DMTONE, that was specially designed to mill the angulated channel.

Our distributor in Poland and the workshop attendees were very thankful for the attention we gave them and highlighted the fact that a company offered them the possibility to visit their facilities and know the “entrails” of the products developed by our engineers. For DAS team, this interaction is essential to innovate in new solutions that make the work of dental professionals easier. Therefore, the visit of these professionals was a very enriching experience for us as well.

We also had some leisure time with the attendees and we prepared a tour around our city.

See you soon!